Eva: Zero-electricity Produce Cooler

EVA is a sustainable, electricity-free cooler designed to triple the freshness of produce by simply watering it regularly. Developed by a team of UX designers and mechanical engineers during the UM Ross School of Business's "Integrated Product Development" course, EVA combines innovation and simplicity to promote eco-friendly food preservation.

Product Design

UX Research

Marketing

Branding

Executive Summary

Our design challenge for this project was: How can we help people manage power outages to meet basic needs, minimize disruptions, and make the best of the situation?

Project Timeline

The project began with the discovery stage, structured over a 15-week timeline. The final week culminated in a trade show, where teams pitched their products to investors and potential buyers, aiming to secure funding and market interest.

01 // EARLY RESEARCH

We conducted semi-structured interviews with 52 participants to uncover their pain points during power outages.

Key quotes from the interviews were used to create an affinity map, grouping similar challenges and concerns into common themes.

Interview Insights

The two primary pain points identified were -

Lack of Preparedness and Reactive Behavior

Many users prepare for power outages only after they occur, often not anticipating long outages.

A significant number of individuals don’t take proactive measures (e.g., maintaining backup supplies, organizing an alternative power source) until the moment an outage begins.

Food spoilage

One of the most common frustrations during power outages is the loss of perishable food, particularly frozen items and fresh produce.

People incur financial lossed as well due to throwing away perishable groceries.

Based on our discoveries from the interviews, the team decided to conduct secondary research on the primary insights — Lack of preparedness and food spoilage.

Secondary Research Insights

How can we help individuals decrease their food waste through sustainable and habit-forming practices?

02 // Product Overview

Introducing Eva

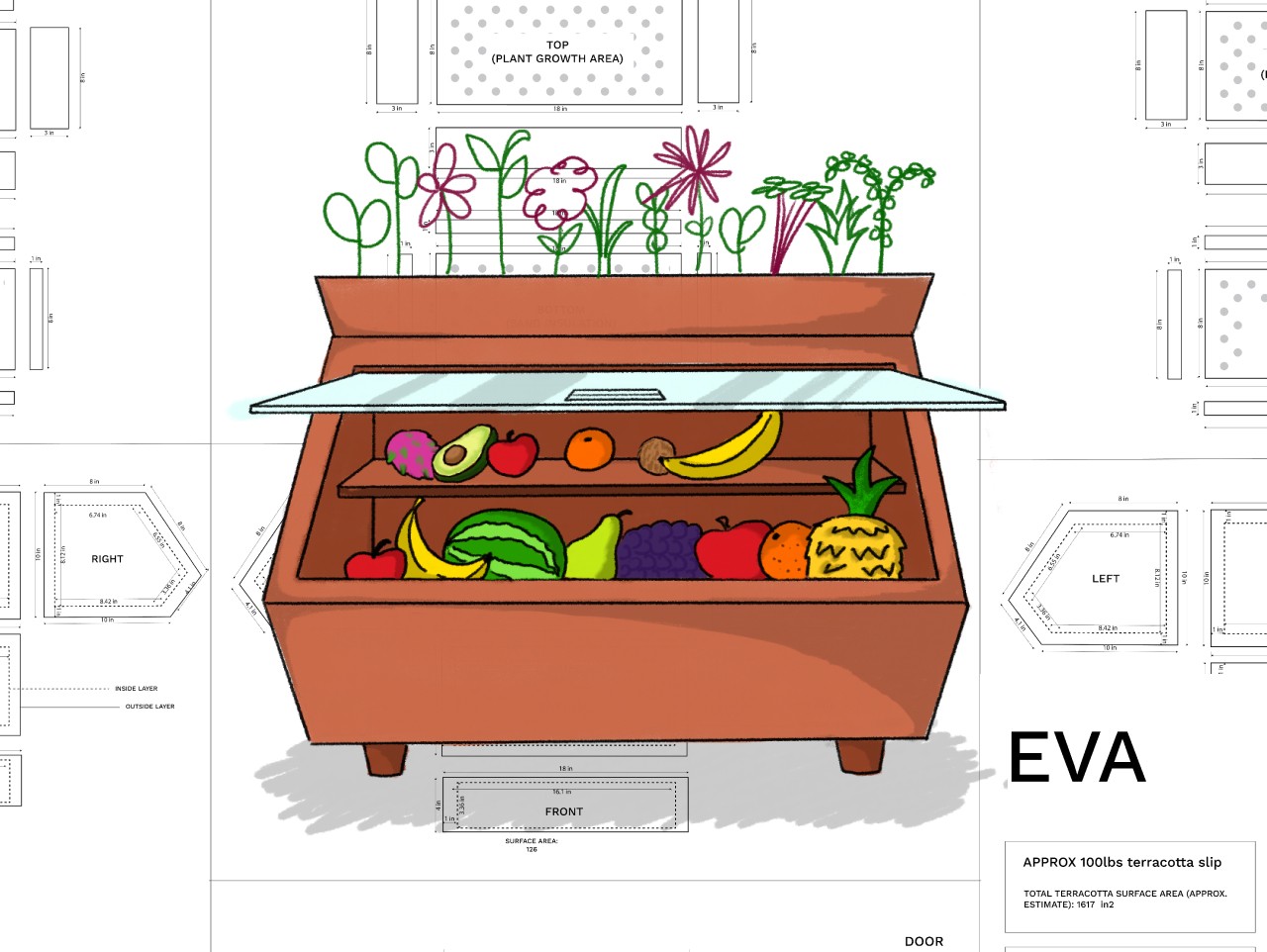

Eva extends the shelf life of your produce by at least two weeks. Its design features two key components: a produce container and a planter on top. No electricity is needed—simply water the plants to maintain a cool environment. The transparent, insulated ceramic door allows easy visibility of the stored produce, combining functionality with sustainability.

Three-Layered Cooling System

The container is designed with three functional layers: an outer glazed terracotta layer, an inner unglazed terracotta layer, and a middle insulating layer filled with sand or clay pebbles. Water from the planter seeps through small openings into the insulating layer, which absorbs and distributes the moisture along the container walls. The porous inner layer then absorbs this moisture, creating a natural evaporative cooling effect that maintains a cool internal temperature, extending the freshness of stored produce.

Optimal Cooling and Humidity Control

Eva maintains a high-humidity environment (20-60%) to preserve moisture levels, allowing it to reach temperatures as low as 40°F, with an operating range of 40-48°F. This natural cooling mechanism helps ensure prolonged freshness and optimal storage conditions for produce.

03 // Concept Generation and Testing

Comparative Analysis

To get started, we conducted a comparative analysis of existing solutions addressing food spoilage. This step allowed us to evaluate current market offerings, identifying strengths, weaknesses, and gaps in user experience. The insights gained from this analysis informed the early stages of our design.

We incorporated these examples into our concept testing phase as well, using them as benchmarks to evaluate our initial product sketches.

Initial Sketches and Prototypes

Initial Storyboarding

We finalized three distinct concepts for concept testing, each designed to explore different user preferences and functionalities.

Based on initial feedback, we incorporated both non-plant-based and plant-based designs to identify which direction participants favored:

Concept 1: A compact, countertop-friendly design utilizing jute fiber pads for insulation, providing a minimalist, space-saving solution.

Concept 2: A larger, outdoor-friendly design with increased storage capacity and transparent doors for improved visibility, catering to users with higher storage needs.

Concept 3: A design inspired by traditional flower pots, blending food storage with a familiar planter aesthetic, designed to emphasize familiarity and ease of integration into home environments.

Concept Testing Insights

Initially, we conducted concept testing with our proposed target audience at the time — the student population. Many college students appreciate and understand the value of investing in sustainable products and healthy lifestyles (like buying produce/caring for plants) - but it is simply not realistic for them to engage in doing so (finances, time constraints).

The older demographic was more receptive to the products -- they gravitated more towards the zero-electricity and self-sustainable aspect of this product.

Concept Testing Pain Points

We shifted our target audience from the student population to an older demographic.

Older households and households with a higher income purchase a larger proportion of produce, practice/purchase according to sustainability, and engage with plant-related care more than younger households.

Personas and Empathy Mapping

Product Dimensions

After finalizing the features we defined the product dimensions to create our first physical prototype.

04 // Prototyping and User Testing

We created the Looks-Like Prototype following the final product dimensions for user testing.

This would user testing participants a better visual idea of the shape and weight of Eva. The cardboard used to make this was a little weighted to match the final product weight as defined by our dimension calculations.

User testing was conducted with 16 participants at the Ann Arbor Farmer's Market — a key location for our target audience.

Pain Points from the User Testing

Project Constraints

During the prototype phase, we encountered key constraints that shaped our decisions:

Limited Budget: With a small, course-assigned budget, we had minimal room for iteration and were restricted to developing a single looks-like/works-like prototype.

Time Restrictions: Given the one-month timeline, including manufacturing lead time and potential delays, we faced difficulties in creating precise terracotta molds to integrate all features, particularly the planter component.

Material Weight: Sand as the insulation layer presented weight concerns. While we explored alternatives, the short timeline forced us to proceed with sand as the insulating material.

With extended time, we would further investigate lightweight insulation alternatives and refine the production workflow to accommodate all proposed design features efficiently.

Keeping the constraints in mind, we created the works-like prototype.

The planter feature was removed and we resorted to a simpler bowl-like design for easier manufacturing for our trade show. For the time being, we used a transparent plastic cover instead of an insulated ceramic cover due to budget limitations. Sand was still used as an insulating layer, but the smaller design tackled the weight issue and the prototype weighed around 20 pounds.

05 // Cost Summary and Marketing

The Cost Analysis defined our product's market price at $65.99.

Marketing Strategy

Potential Stores to Sell - local oriented

Wide Scope Selling

Suitable Locations to sell in US

Eva Style Guide

06 // Outcome

We presented Eva during the final week’s Trade Show

Here, every participant was given hypothetical $200 dollars to invest in any one of the teams' products. We pitched Eva to investors and potential buyers, and with the market price set at $65.99 and a proposed stock of 20,000 units, we made a gross profit of over a million dollars.

The product received high praise from attendees, who were impressed by its ability to function without electricity and maintain a cool interior, demonstrating its practicality and innovation.

Future Scope

During the trade show, our marketing strategy emphasized that we weren’t just selling Eva as a product, but as a concept. Natural evaporative cooling, a technique used for thousands of years, is largely overlooked in modern first-world nations. In today’s tech-driven society seeking sustainability and environmental responsibility, Eva reintroduces this ancient concept with potential applications beyond food storage.

Given more time and resources, we would have conducted additional research to explore new domains where evaporative cooling could be implemented and expanded our product line. While Eva and its initial concepts served as the foundation, our vision included further development of these products, which we would have ideally presented at the trade show as well.

Key Takeaways

Adapting to Constraints:

One of the biggest lessons from this project was learning how to adapt to circumstances and work within constraints. When we had to redesign Eva and remove the planter aspect due to budget and time limitations, it was initially disappointing for the team. We consulted experienced product designers, who emphasized that constraints are a natural part of product development. They showed us how experienced designers navigate these limitations and still deliver successful outcomes.The Importance of a Minimum Viable Product (MVP):

While products can have multiple unique value propositions, it is essential to first define and refine the core value before expanding. Initially, we explored various aspects of Eva, from cooling to gardening. However, we realized that the primary value lay in evaporative cooling, and that’s where we needed to focus. Attendees at the trade show resonated strongly with this refined message and responded positively to the product’s cooling capabilities. Had we included too many features, it likely would have diluted the core value, reducing its overall impact.User-Centric Design:

Keeping users involved throughout the design process was critical to Eva’s success. From identifying key issues during power outages, stating their pain points during concept testing, to gathering feedback on our prototypes, users played a vital role in shaping the product. Their feedback guided decisions on design refinements and ensured that the final product addressed real needs, ultimately making Eva a viable and practical solution.

02 // Product Overview